Mercedes-Benz Diesel Engines

Finding further potentials within the constraints imposed by physics

In the medium term, the internal combustion engine will maintain its dominant position as a vehicle drive system while acting as a pathfinder towards electric mobility. MTZ interviewed Bernhard Heil, Head of Development Passenger Car Engines and Powertrain at Mercedes-Benz, what to expect up to the year 2020.

|

MTZ: In the light of the electrification debate, is it even worth still

investing in conventional powertrains with a petrol or diesel engine?

Heil: Absolutely. In the past five years alone, we have made quantum leaps in the development of powertrains. In our 7G-Tronic automatic transmission, we have succeeded in reducing fuel consumption by up to 7 % due to a wider gear ratio spread and friction optimisation. And development is not at a standstill. We are already working on the next generation, in which we will use the benefits of this transmission even more consistently. As far as the engines are concerned, we have introduced the third generation of DI engines with piezo injection and lean combustion. In these engines, we have succeeded in extending the map area of the lean combustion process to an extent that we didn't believe possible at the beginning. This enabled us for the first time to certify a spark-ignition engine on the same CO2 level as a diesel engine.

Which further developments can we expect from Mercedes-Benz by the year 2020?

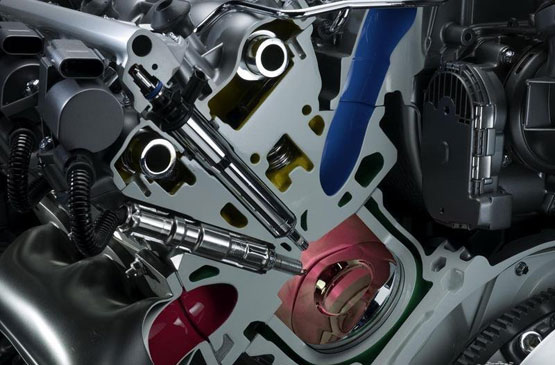

We will continue to optimise the combustion process in the spark-ignition engine in order to improve the lean running capability of the engine. This will require intensive further development on the injection system. Today, Mercedes-Benz is the only manufacturer to offer spark-ignition engines with jet-guided combustion processes and centrally arranged piezo injectors in series production. From our point of view, that is the right way. We are the leaders in combustion efficiency and intend to remain so. Furthermore, supercharging is becoming increasingly important. We are much more committed than our competitors, for example through our joint venture with IHI, in which we are actively promoting further developments with our partners. As a third element, we are continuing to focus on the subject of exhaust aftertreatment, in both diesel and spark-ignition engines.

In spark-ignition direct injection systems, system pressures are currently 200 bar. What will be possible, and worthwhile, in the future?

We are constantly examining further developments in fuel injection systems very precisely to check whether we can further increase the stratification capability of the engines by increases in pressure. From today's perspective, we are in a very good position with our 200 bar systems. At the moment, we are concentrating on making even better use of the possibilities that the piezo system offers with regard to multiple injections in order to further extend the stratification capability of the engines.

What are the limits to downsizing in spark-ignition engines?

With the comfort demands that we formulate for ourselves, I would say in the magnitude of 100 kW/l, or perhaps a little higher.

In the 1990s, you used compressor supercharging in spark-ignition engines. Are you still working on mechanical supercharging alongside turbocharging?

At that time, compressor supercharging was the best technology, also because our transmissions did not have such a wide gear ratio spread as today. The driveaway behaviour and non-steady-state characteristics of a turbocharged engine did not fully meet our comfort requirements. Today, our transmissions have a wider spread, the turbochargers have been considerably further developed and we can also further optimise the combustion process for turbocharging by using variable camshafts and direct fuel injection. For that reason, our focus is on exhaust gas turbocharging.

Dual-clutch transmissions or automatic transmissions with a torque converter which system will be predominant in the future?

For our classic model series, we will continue to offer our torque converter automatic transmissions. Firstly, an automatic transmission with a torque converter offers unsurpassed comfort when pulling away from a standstill. Secondly, the increased driveaway torque is a further comfort aspect, as we do not have to work with the very shortest driveaway gear ratios. What is more, torque converter automatic transmissions can be very well integrated into our standard powertrain package. From a fuel consumption point of view, all measurements show that the torque converter automatic transmission is the most efficient solution in our classic series. For model series with front-wheel drive, the installation space available determines the technical possibilities. A torque converter automatic transmission is approximately 30 to 40 mm longer than a dual-clutch transmission, so it does not make sense to integrate it into the front-end structures. Therefore, for cars with front-wheel drive, we will focus on dual-clutch transmissions in the future.

We are now hearing much less about the Diesotto engine, which was greatly publicised a short time ago. Are you still working on it?

Our aim is to make petrol engines as efficient as diesel engines and make diesel engines as clean as petrol engines. As far as diesel engines are concerned, the use of particulate filters and our BlueTec technology have enabled emissions to be reduced almost to the level of spark-ignition engines. We are now working on making the spark-ignition engine as fuel-efficient as the diesel. We included all these aspects under the working title "Diesotto". The spark-ignition engine is benefiting from many technology components that were previously familiar from the diesel engine. For example, these include turbocharging and direct injection. In other words, there is already a great deal of Diesotto in our new BlueDirect engines.

How great is the potential for CO2 reduction as a result of the system optimisation of all powertrain components by 2020?

We will not be able to change the limits of the Carnot Cycle, so our aim will be to find further potentials within the constraints imposed by physics. I am sure that we can achieve further improvements by optimising stratification processes and downsizing, for example to achieve the power output of current six-cylinder engines with four-cylinder engines in the future. With regard to transmissions, we are considering gear ratio spreads and numbers of gears. For larger vehicles, further potentials can be found in hybridisation and, for smaller vehicles, in electrification.

What will be the dominant engine in the future, the petrol or diesel engine?

We can see a further increasing trend towards petrol engines. The growth markets of India, China or Russia in particular are classic petrol engine markets. Diesel fuel will be concentrated very strongly on goods traffic, in other words trucks, trains and ships. For these applications, any solution away from the diesel engine is very unlikely. In Europe, the situation is completely different. The high proportion of diesel vehicles was one of the main reasons for progress in fleet fuel consumption and CO2. What is more, the diesel engine is unbeatable with regard to torque. This will contribute to the fact that modern and clean diesel engines will continue to enjoy a high level of popularity.

Will there still be any powertrains at all without electrification?

We can argue about the market penetration of hybridisation. I am sure that we will see a considerable proportion of hybrid vehicles in 2020. We at Mercedes-Benz also see a market for large premium vehicles in the future, provided that they are environmentally compatible. For that reason, our approach is to further improve the efficiency of our vehicles by an increasing use of electrification and to continue to offer our customers comfortable, safe and dynamic premium cars in the future.

Do you see pure electric mobility coming more from the lower end of the market?

Electric mobility will initially have relevance in the segment of smaller vehicles because, in that segment, the required driving ranges are not as great as to demand an additional internal combustion engine as a range extender. This means that we can open up the subject of electric mobility to a relatively large customer group. An electric vehicle with a range of 100 km being used purely as a second car seems to me to be a perfectly reasonable proposition. For the classic Mercedes model series, I see a different route: initially, further optimisation of the internal combustion engine, then hybridisation, and then the plug-in hybrid, to enable people to drive in zero emission zones.

Bernhard Heil, thank you very much for this interview.

Mercedes-Benz 3.0 liter V6 turbodiesel info file: pdf file, 11 pages

2005

World record for Mercedes-Benz new V6 turbodiesel OM642 (in E320 CDI)

- 100,000 miles at an average speed of 224.823 km/h / 139.696 mph

- Record distance equal to four times around the world

- Endurance test for the Mercedes E 320 CDI, 30 days of relentless, round-the-clock punishment

- Proof of the performance of the diesel particulate filter

Three E320 CDI using the new OM642 3.0 liter V6 turbodiesel were driven

100,000 miles within 30 days at the 5 mile oval racetrack in Laredo, Texas

and set several FIA world endurance records to demonstrate the reliability

and efficiency of the new common rail direction injection turbodiesels.

The engine oil was changed 10 times, every 15,000 kilometers.

2005

4.6 million kilometers: new record

A Greek taxi driver, Gregorios Sachinides, presented the

Mercedes-Benz museum in Stuttgart with his trusty cab - a 1976 Mercedes

240D diesel with 4.6 million kilometres on the clock.

2004

|

diesel Diesel DIESEL diesel Diesel DIESEL diesel Diesel DIESEL diesel Diesel DIESEL |